- Welcome To Changzhou Huarui Welding & Cutting Machinery Co., Ltd.!

- About Huarui | Inquiry Form | Contact Us |

中文

中文

中文

中文What is a conductive mouth

Conductive nozzle is: welding equipment wearing parts, belong to welding consumables, the tail part of the welding gun, the metal nozzle that sends the welding wire, called conductive nozzle.

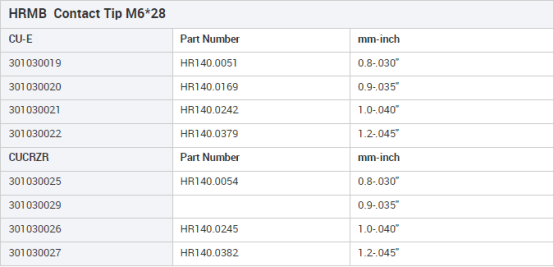

Generally brass, copper, chrome zirconium copper, beryllium copper. Copper conductive nozzle is commonly used, chromium-zirconium copper material is better than copper, more durable. Ceramic makes conductive mouth, later due to performance and other problems were eliminated. The conductive nozzle is classified according to the specification diagram. Commonly used are co2 gas welding machine with conductive nozzle, submerged arc welding conductive nozzle, electrode.

In the European and American welding gun, mainly with copper conductive nozzle, in the Japanese and Korean welding gun is mainly equipped with chromium zirconium copper conductive nozzle. It is mainly used in Europe and the United States as a protective gas with argon as the main mixed gas, with long arc and poor gas cooling performance. The main way of the failure of the conductive nozzle is caused by the micro arc between the inner hole wall of the conductive nozzle and the welding wire. Therefore, red copper with better conductivity and thermal conductivity is used as the conductive nozzle, while CO2 gas is used as the protective gas in Asia, with short arc and strong gas cooling ability. Japan believes that the failure of the conductive nozzle is mainly caused by the friction loss between the inner hole wall of the conductive nozzle and the welding wire, so the rigid chrome-zirconium copper material is mainly used. As China mainly uses CO2 gas as a protective gas, chrome-zirconium copper conductive nozzle should be selected.

What are the functions and structural forms of gas welding conductive nozzle

In order to more steadily direct the current to the arc area, a copper nozzle is installed at the outlet of the torch. It can increase the service life of the conductive nozzle, enhance the stability of the welding process and improve the ability of conducting current. According to different requirements, the conductive nozzle is designed into seven forms: cone, oval, insert, cone table, cylinder, semicircle and roller.

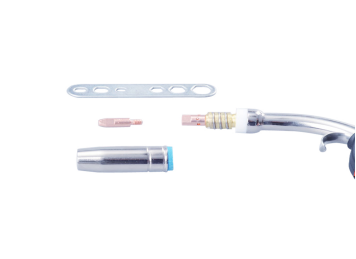

Huarui Contact Tip For MB25AK 24KD 26KD 36KD Mig Welding Spare Parts

welcome to our alibaba shop:

https://czhuarui.en.alibaba.com/

https://topwelding.en.alibaba.com/

master@huarui-cn.com

master@huarui-cn.com 86-519-86371071

86-519-86371071 86-519-86371072

86-519-86371072

View More(Total0)Comment Lists