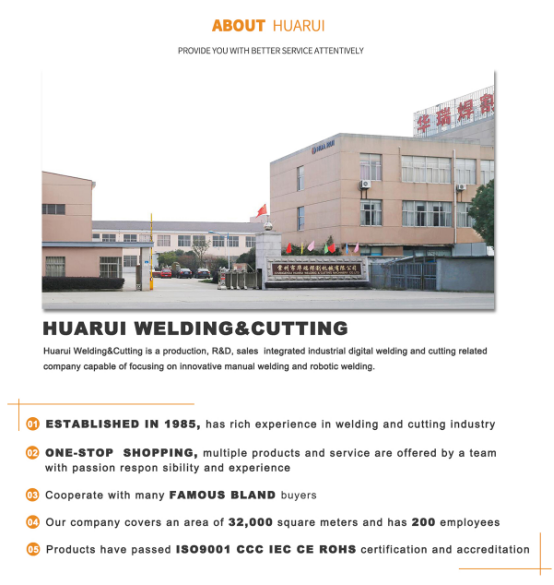

- Welcome To Changzhou Huarui Welding & Cutting Machinery Co., Ltd.!

- About Huarui | Inquiry Form | Contact Us |

中文

中文

中文

中文In the structure of the boiler, pressure vessel, pressure pipe welding, the joint must be completely melted through, but some joints can not be in the back root or rewelding can not meet the requirements, then we must use single-side welding double-sided forming technology.

Single-side welding and double-sided forming technology refers to the operation process of welding from the front of the groove of the welded part to achieve the formation of a dense and uniform weld at the same time.

It is the selection of ordinary electrode or special bottom electrode welding, using different operation techniques to make the base metal groove blunt edge metal regularly melted into a certain size of the weld hole, in the arc action on the front weld pool at the same time, so that 1/3~2/3 arc through the weld hole and the formation of both sides are uniform and neat, forming good, in line with the quality requirements.

Two bottom operation

Continuous arc welding method and arc extinguishing welding (also known as broken arc welding) method of two categories:

(1) Even arc welding at the bottom, after the arc is ignited, artificial arc extinguishing is not allowed in the middle, and it must be a short arc continuous transport until the replacement of another electrode is extinguished.

(2) When the arc extinguishing welding method is laid, the arc is rhythmically started and extinguished, so as to control the temperature of the molten pool and form the single-side welding and double-sided forming.

Arc extinguishing welding base operation method

One-click threading method: when the arc is burned on both sides of the groove, the metal on both sides of the blunt edge is melted to form a melting hole at the same time, and then the arc is quickly extinguished. When the molten pool is about to solidify (dark red), the arc is ignited at the arc extinguishing place, and the operation is repeated in turn.

Suitable for: One click threading method is suitable for the welding of thin plate, small diameter pipe (≤φ60mm) and small gap (1.5~2.5mm).

Advantages: One click threading is not easy to appear slag inclusion, porosity and other welding defects.

Disadvantages: the temperature of molten pool is not easy to control, low temperature, easy to appear not welded through; High temperature, the back of the residual high is too large, even appear welding tumor.

Two-click threading method: The arc is ignited alternately on both sides of the groove, that is, a drop of metal is melted at the right blunt edge, and then a drop of metal is melted at the left blunt edge, and so on.

Suitable for:welding of thick plate, large diameter tube and large gap.

Advantages: Two-click threading is easy to master, the temperature of the molten pool is easy to control, and the blunt edge fusion is good.

Disadvantages: easy to appear slag inclusion, porosity and other welding defects.

Three-click threading method: After the arc is ignited, a drop of metal is melted at the left blunt edge, a drop of metal is melted at the right blunt edge, and then a drop of metal is melted at the middle gap.

Advantages: Three click threading method is suitable for the base of the larger gap.

Disadvantages: the back is prone to cold shrinkage hole defects.

Essentials of arc extinguishing welding operation

First: look at the shape of the molten pool and the size of the molten hole, and distinguish between molten slag and molten metal.

Second: listen to the sound of arc breakdown groove root, when the arc breakdown groove root, will emit a "poof poof" sound, which indicates that the weld penetration is good. If there is no such sound, it indicates that the groove root is not broken down by arc. If welding continues, it will cause incomplete welding.

Three :accurately grasp the size of the formation of the weld hole, generally on both sides of the blunt edge need to melt 0.1~1 mm.

Four : ensure that the arc break and re-ignition time interval is short, generally not more than 1s.

Arc extinguishing welding and arc closing technique

In the replacement of the electrode arc, should be the electrode to the root of the top pressure, so that the weld hole in front of the molten pool slightly expanded, at the same time to improve the arc extinguishing, arc burning frequency, filled with arc pit, so that the molten pool slow cooling and full, prevent shrinkage hole and arc pit cracks.

master@huarui-cn.com

master@huarui-cn.com 86-519-86371071

86-519-86371071 86-519-86371072

86-519-86371072

View More(Total0)Comment Lists