- Welcome To Changzhou Huarui Welding & Cutting Machinery Co., Ltd.!

- About Huarui | Inquiry Form | Contact Us |

中文

中文

中文

中文Welding rod will often be due to moisture absorption and the process performance deteriorates, resulting in arc instability, spatter increase, and easy to produce pores, cracks and other defects. Therefore, the electrode must be strictly dried before use.

General acid electrode drying temperature 150 ~ 200℃, time 1 hour; The drying temperature of alkaline electrode is 350 ~ 400℃, and the time is 1 ~ 2 hours. After drying, it is placed in the thermal insulation box of 100 ~ 150℃.

After the electrode is damp, the general medicine skin color is dark, the electrode collision loses the crisp metal sound。

Influence of damp electrode on welding process:

(1) The arc is unstable, the splash is increased, and the particles are too large.

(2) deep penetration, easy to bite edge.

(3) The slag is not covered well and the welding wave is rough.

(4) It is difficult to remove slag.

Influence of damp electrode on welding quality:

(1) easy to cause welding cracks and pores, especially alkaline electrode.

(2) The values of mechanical properties are easy to be low.

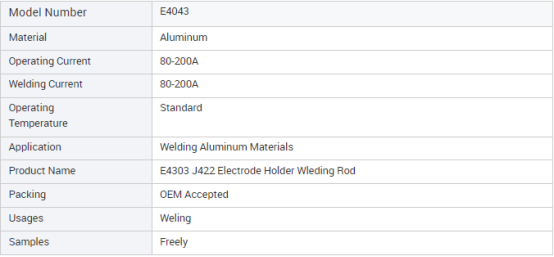

HUARUI E4303 J422 Electrode Holder Wleding Rod Welding Electrode Low Carbon Steel Welding Rod

welcome to our alibaba shop:

https://czhuarui.en.alibaba.com/

https://topwelding.en.alibaba.com/

master@huarui-cn.com

master@huarui-cn.com 86-519-86371071

86-519-86371071 86-519-86371072

86-519-86371072

View More(Total0)Comment Lists