- Welcome To Changzhou Huarui Welding & Cutting Machinery Co., Ltd.!

- About Huarui | Inquiry Form | Contact Us |

中文

中文

中文

中文

Technical background

Push and draw fuse gas shielded welding gun is widely used in industrial manufacturing. Compared with the ordinary push-wire welding gun, the push-wire welding gun comes with a motor. When working, the motor on the front of the welding gun pulls the welding wire, and the motor on the welding machine pushes the welding wire, the wire feeding distance can reach 12 meters or even farther, and the longest of the ordinary push-wire welding gun can only do about 5 meters. Because the welding wire tray is on the welding machine, you can use a large welding wire tray, and the melting rate is the same as that of the ordinary push wire welding gun.

In aluminum or copper welding, because the welding wire is soft, it is easy to plug the wire in the process of pushing the wire, so the length of the welding gun for soft welding wire can only be about 3 meters, then the advantages of pushing and drawing the welding gun in length are more obvious. In the actual industrial production, the push and draw welding gun is mainly used for welding with soft welding wire. In recent years, with the national efforts to promote energy saving and efficiency improvement and the development of molten gas welding technology, molten gas welding is more and more applied in the welding field of aluminum alloy, and more and more application places of push-draw welding gun.

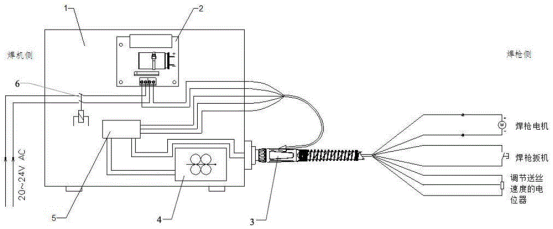

Push-draw welding gun, as a kind of welding auxiliary equipment, must be used with welding machine and related protective gas, but most of the existing fuse gas shielded welding machines do not support push-draw welding gun. If the user needs to use the push-draw type welding gun, it is necessary to buy a welding machine supporting the push-draw type welding gun or install synchronous drive on the existing machine. The former requires a large amount of capital, which is not allowed economically when the usage rate is not high, the latter requires complex wiring and installation, the need for independent power supply, and the motor drive tension is unstable, the effect is not ideal. Attached Figure 1 is the wiring diagram of the independent control circuit board of the prior art wire-drawing welding gun. The control board of the wire-drawing motor 2 is fixed in the wire feeder 1 at the side of the welding machine. The independent power supply is connected through relay 6, and the welding gun is connected through the cable. Wire pusher motor controller 5 connects to wire pusher motor 4 through wire pusher motor connection, and welding gun 3 through welding gun control line. In this connection mode, an independent power supply is needed, and a relay needs to be connected to control the on and off of the power supply. The relay is generally controlled by the power supply of the air supply valve. The wiring mode is complex, and the power of pulling the welding wire is not constant, and the current limiting resistance above is easy to heat.

Although some welding machines support push-draw welding gun, but because of the different welding machine manufacturers design wire-drawing welding gun drive circuit, users purchase push-draw welding gun need to inform the manufacturer of motor parameters, potentiometer parameters and wiring mode and other information, the manufacturer begins production after receiving the order. This causes long order cycle, small batch, inventory pressure and high production costs.

Moreover, different motor parameters are not the same, the control mode of the push and draw welding gun has very strict requirements on the parameters of the welding gun motor, sometimes only the same parameters can be used, otherwise it can not work normally.

Basic method of welding with push-draw welding gun

1. welding temperature

TBi air cooled push wire drawing welding gun material polyethylene polypropylene ABS hard PVC polyformaldehyde polycarbonate

TBi air cooled push wire drawing welding gun Temperature: 250-280 220-230 230-250 220-240 270-300 260-280

2. welding method:

The welding gun nozzle is aligned with the electrode, in order to make the electrode and the welding place heated at the same time, push the wire drawing welding gun, the welding gun should be fan-shaped swing between the weld and the electrode, when the electrode is softened, the constant pressure is applied to the welding strip, and the nozzle of the welding gun is slowly welded from left to right. The Angle of the nozzle of the plastic welding gun and the surface of the base material depends on the thickness of the base material and the temperature of the hot air. Generally, the tilt Angle is 25°-45°, and the distance between the nozzle and the weld surface should be about 10mm. The swing speed of the plastic welding gun is generally 2 times per second, and the swing is about 10mm.

Attention

Spot welding Electrode spot welding is usually divided into two sided spot welding and single side spot welding. Push the wire drawing welding gun to push the wire drawing welding gun to push the wire drawing welding gun, the electrode from both sides of the workpiece to the welding. Typical double-sided spot welding is commonly used, when both sides of the workpiece have electrode indentation. Spot welding of large welding area of conductive plate as the lower electrode, so as to eliminate or reduce the indentation of the workpiece below. Generally used for spot welding of decorative panels. At the same time welding two or more double-sided spot welding, with a transformer to connect the electrodes in parallel, at this time, the impedance of all current paths must be basically equal, and the surface state of each welding position, material thickness, electrode pressure must be the same, push and draw wire welding gun to ensure that the current through each spot is basically the same, using multiple transformers double-sided multi-point spot welding, This will avoid shortfalls

The fault is divided into mechanical fault and electrical fault

(1) Mechanical failure

Fault symptoms.

1, the wind pressure is reduced, the air volume is reduced;

2, the air pump shell is crackling;

3, vibration is too large;

These failures are caused by the wear of the motor bearing, the use of the carbon brush of the push and draw welding gun, the deformation of the impeller or the foreign body in the impeller and other reasons; This fault can be checked around the motor shaft

Whether the swing is too large, wind leaf and other parts can be solved; If the blade or rectifying ring should be replaced, special attention should be paid to their installation direction push wire drawing welding gun

(2) Electrical faults

1, the temperature is too high, may be silicon controlled short circuit (use a multimeter to measure T1, T2 resistance is 0Ω) or temperature controller failure; Push and draw welding gun

2, Adjust the temperature regulator knob, can adjust the temperature, but can not be adjusted to the cold air, TBi360 push wire drawing welding gun, with ammeter measurement, ammeter pointer between 2A-4.5A, can not go back At about 0.5A, the temperature controller fails; Push and draw welding gun

3, the use of sudden cooling, temperature controller failure, heater circuit (use a multimeter to measure the resistance between the heater pins, the normal value is about 50Ω) or Thyristor damage;

4, in the use of the process, the temperature is high and low, it may be damaged potentiometer or a wire joint loose resulting in poor contact.

5. When running, the speed drops sharply and the wind pressure drops significantly, it may be the motor is damaged. The temperature controller knob should be immediately adjusted to "1" to push and draw the wire welding gun, and the TBi air cold push and draw the wire welding gun should be repaired after the barrel is cooled.

master@huarui-cn.com

master@huarui-cn.com 86-519-86371071

86-519-86371071 86-519-86371072

86-519-86371072

View More(Total0)Comment Lists