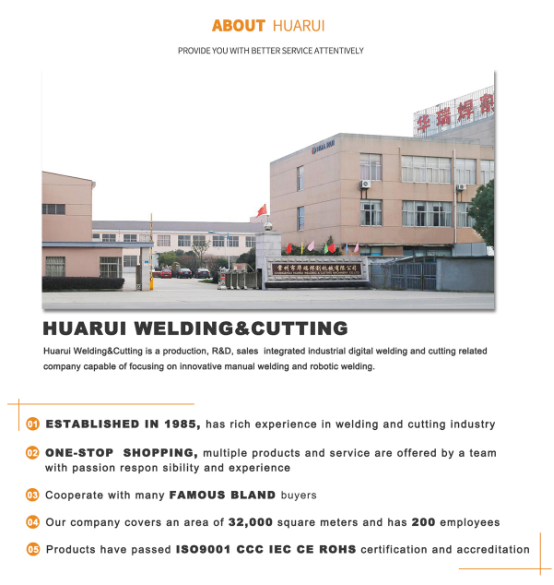

- Welcome To Changzhou Huarui Welding & Cutting Machinery Co., Ltd.!

- About Huarui | Inquiry Form | Contact Us |

中文

中文

中文

中文The selection of electrode must be in ensure the safety and reliable use of welding structure, according to the chemical composition of the welding material, mechanical properties, plate thickness and joint form, welding structure characteristics, stress state, structural conditions, the requirements of weld performance, welding construction conditions and technical and economic benefits, targeted selection, if necessary, also need to carry out welding performance test.

Same steel welding electrode selection points

1. Consider the mechanical properties and chemical composition of weld metal

For common structural steel, the strength of weld metal and base metal is usually required, and the tensile strength of fused metal equal to or slightly higher than that of base metal should be selected. For alloy structural steels, the alloy composition is sometimes required to be the same or close to that of the base metal. The welding rod with lower strength than the base metal should be considered when the welding structure is rigid, the joint stress is high and the weld is easy to crack. When the content of carbon, sulfur, phosphorus and other elements in the base metal is high, cracks are easy to occur in the weld, and alkaline low hydrogen electrode with good cracking resistance should be selected.

1. Consider the performance and working conditions of welded components

For the welding parts under dynamic load and impact load, in addition to meeting the strength requirements, the main thing should be to ensure that the weld metal has high impact toughness and plasticity, and the low hydrogen electrode with high plasticity and toughness index can be selected. For welds in contact with corrosive media, stainless steel electrode or other corrosion resistant electrode should be selected according to the nature and corrosion characteristics of the medium. For welding parts working under high temperature, low temperature or other special conditions, corresponding heat resistant steel, low temperature steel, surfacing or other special diagnostic electrodes shall be selected.

1. Consider the characteristics of welding structure and stress conditions

For the thick and rigid welding parts with complex structure and shape, due to the great internal stress produced in the welding process, it is easy to crack the weld, so the alkaline electrode with good cracking resistance should be selected. On the force is not large, welding parts difficult to clean up, should choose to rust, oxide skin, oil sensitive acid electrode. For welding parts that cannot be turned over due to conditions, the electrode suitable for all-position welding should be selected.

4. Consider construction conditions and economic benefits

In the case of meeting the requirements of product performance, the acid electrode with good technology should be selected. In narrow or poor ventilation conditions, should choose acid electrode or low dust electrode. For the structure of large welding workload, conditions should be as far as possible to use high efficiency electrode, such as iron powder electrode, high efficiency gravity electrode, or the selection of the bottom electrode, vertical downward electrode and other special electrode, in order to improve welding productivity.

Key points of welding rod selection in dissimilar steel welding

1. Carbon steel ten low alloy steel with different strength levels

(Or low alloy steel ten low alloy high strength steel)

1. Low alloy gold steel + austenitic stainless steel

Low alloy steel + austenitic stainless steel should be selected in accordance with the limited value of the chemical composition of the molten metal, the general selection of chromium, nickel content is higher, plastic, crack resistance is better Cr25-N; Type 13 austenitic steel electrode to avoid cracks due to the formation of brittle hardened microstructure. But the welding process and specification should be determined according to the poor welding of stainless steel.

3. Stainless steel composite steel plate

Stainless steel composite steel plate should be considered for the base, cladding, transition layer welding requirements of three different performance of the electrode. For the welding of the base (carbon steel or low alloy steel), the corresponding strength grade of structural steel electrode is selected; The coating is directly in contact with the corrosive medium, and the austenitic stainless steel electrode of the corresponding composition should be selected. The key is the welding of the transition layer (that is, the interface between the coating and the base layer). The dilution effect of the substrate material must be considered, and the Cr25-Ni13 austenitic steel electrode with high chromium and nickel content, good plasticity and crack resistance should be selected.

master@huarui-cn.com

master@huarui-cn.com 86-519-86371071

86-519-86371071 86-519-86371072

86-519-86371072

View More(Total0)Comment Lists