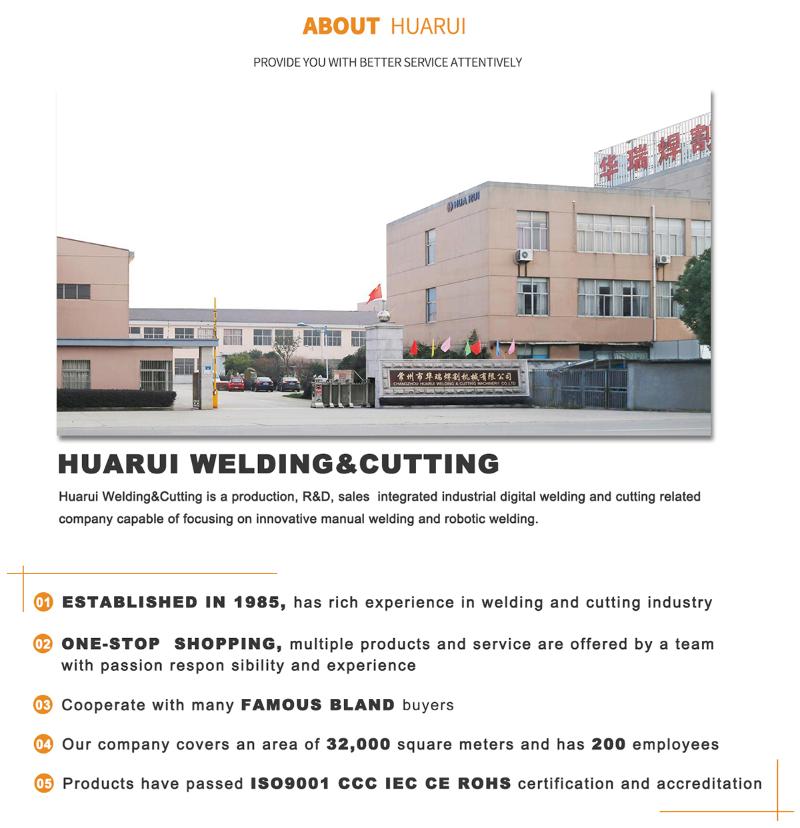

- Welcome To Changzhou Huarui Welding & Cutting Machinery Co., Ltd.!

- About Huarui | Inquiry Form | Contact Us |

中文

中文

中文

中文Methods to prevent welding cracks

1. Select materials correctly

Choose alkaline low-hydrogen electrode and flux to reduce the content of diffused hydrogen in weld metal; Do a good job in the selection of base material and welding material matching; If the technical conditions permit, materials with good toughness (such as welding materials with a lower strength level) can be selected, or "soft" covers can be implemented to reduce the residual stress on the surface; If necessary, chemical analysis, mechanical properties, weldability and crack sensitivity tests are carried out on the base material and welding material before manufacturing.

2. Welding operation is carried out in strict accordance with the correct process specifications obtained by the test

Mainly includes: strictly according to the specification of welding rod drying; Select appropriate welding specifications and wire energy, reasonable current, voltage, welding speed, interlayer temperature and correct welding sequence; Check and treat spot welding; Clean the root of double-sided welding; Carefully clean the groove and welding wire to remove oil, rust and moisture.

3. Select a reasonable welding structure to avoid excessive restraint stress; Correct groove form and welding sequence; Reduce the peak of welding residual stress.

4. Preheating before welding, slow cooling after welding, controlling interlayer temperature and post-welding heat treatment are effective methods to prevent cold cracks for high-strength steel with poor weldability and unavoidable high-restraint structural forms. Preheating and slow cooling can slow down the cooling rate (prolong the residence time of △t 800~500℃), improve the microstructure of the joint, reduce the hardening tendency, and reduce the microstructure stress; Post-welding heat treatment can eliminate welding residual stress and reduce the content of diffused hydrogen in the weld. In most cases, stress relief heat treatment should be carried out immediately after welding.

5. Hammering immediately after welding to disperse the residual stress and avoid causing high stress areas is one of the effective ways to prevent cold cracks during local repair welding.

6. In the weld root and the weld surface where the stress is relatively concentrated (the restraint stress of the heat affected zone is low), the welding rod with lower strength level is often used to achieve good results under high restraint.

7. The use of inert gas shielded welding can maximize the control of the hydrogen content of the weld and reduce the sensitivity of cold cracks, so TIG and MIG welding should be vigorously promoted.

Method of preventing welding hot crack

1. Limit the content of elements and harmful impurities that are prone to segregation in steel and welding materials, especially the content of S, P, and C, because they not only form low melting point eutectic, but also promote segregation. C≤0.10% thermal crack sensitivity can be greatly reduced. If necessary, chemical analysis of the material, low power inspection (such as sulfur printing, etc.).

2. Adjust the chemical composition of weld metal, improve the organization, refine the grain, improve plasticity, change the shape and distribution of harmful impurities, reduce segregation, such as the use of austenite plus less than 6% of the ferrite biphase structure.

3. Improve the basicity of the electrode and flux to reduce the content of impurities in the weld and improve the degree of segregation.

4. Select a reasonable groove form, weld forming coefficient ψ=b/h > 1, avoid narrow and deep "pear-shaped" weld, (welding current is too large will form a "pear-shaped" weld), prevent the cylindrical crystal in the center of the weld, resulting in center segregation to form a brittle section; Multi-layer and multi-pass welding is adopted to disrupt segregation aggregation.

5. The use of small (appropriate) welding line energy, for austenitic (nickel-based) stainless steel should try to use a small welding line energy (no preheating, no swing or less swing, fast welding, small current), strict control of the interlayer temperature, in order to shorten the residence time of weld metal in the high temperature zone;

6. Pay attention to the protection of arc retraction, arc retraction should be slow and fill the arc pit to prevent the thermal crack caused by arc pit segregation;

7. Try to avoid multiple repairs to prevent lattice defects from gathering and producing polygonal hot cracks;

8. Take measures to minimize the joint stress, avoid stress concentration, and reduce the stiffness near the weld, properly arrange the welding order, and try to make most of the weld welding under a small stiffness, so that it has room for shrinkage.

Methods to prevent reheat cracking

1. When selecting materials, attention should be paid to the carbide forming elements that can cause precipitation, especially the content of V. When high V steel must be used, special attention should be paid to welding and heat treatment.

2. Avoid the reheat sensitive area during heat treatment, which can reduce the possibility of reheat crack, and do heat treatment process test before heat treatment if necessary.

3. Minimize residual stress and stress concentration, reduce residual height, eliminate edge bite, incomplete penetration and other defects, and polish residual height and weld toe smoothly if necessary; Increase preheating temperature, slow cooling after welding, reduce residual stress.

4. Appropriate line energy to prevent heat affected zone from overheating and coarse grains.

5. Under the premise of meeting the design requirements, choose a lower strength grade of the electrode to release a part of the stress eliminated by the heat treatment process (let the stress relax in the weld), which is good for reducing reheat cracks.

HUARUI alibaba shop:

https://topwelding.en.alibaba.com

https://czhuarui.en.alibaba.com

master@huarui-cn.com

master@huarui-cn.com 86-519-86371071

86-519-86371071 86-519-86371072

86-519-86371072

View More(Total0)Comment Lists