- Welcome To Changzhou Huarui Welding & Cutting Machinery Co., Ltd.!

- About Huarui | Inquiry Form | Contact Us |

中文

中文

中文

中文Fillet weld is the most common weld splicing form in the welding process of steel structure, so many welders will encounter different styles of fillet weld, but also have different standards, so how to weld good fillet weld, and to meet the requirements?

1.Selection of base material

we take the base material Q355, size of 200x125x12mm test plate as an example for a simple introduction.

2.Selection of welding materials

Welding material: E5015 (J507) electrode is selected, the drying temperature is 350℃, and the heat preservation is 1 hour. The welding wire meets the national standard ER50-6 (American standard ER70S-6).

3.Pre-weld cleaning

For fillet welds, both sides of the weld should be cleaned within 15~20mm. The oxide film, rust, oil and water on the surface of the plate are removed by grinding wheel or chemical treatment.

4. Assembly point fixation

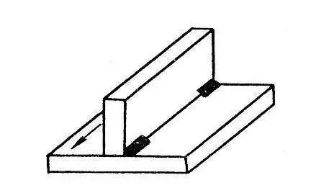

Generally, fillet welds require as little weld clearance as possible. Point fixing is generally carried out on the back of the plate, point fixing length is about 10mm. Generally, two or three points can be fixed, as shown in the figure:

Bottom welding

1.1 Angle of electrode and method of transporting electrode.

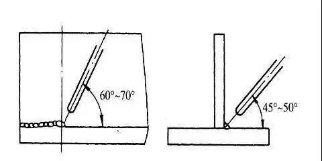

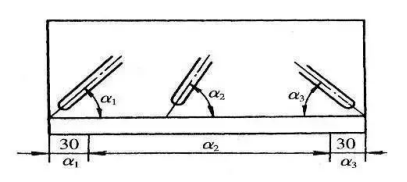

The Angle of the electrode for flat fillet welding at the root is shown in the figure: right welding method is adopted, and arc is initiated on the left side of the test plate for short arc welding. Adopt straight line transport, welding to the right, arc aligned with the top Angle of the root, low arc, ensure that the top Angle and the two sides of the plate fusion. When the bottom welding swing method adopts the straight line, no swing fast welding, so that the required penetration can be achieved.

At the beginning and end of the weld, it is easy to appear magnetic bias phenomenon, which affects the quality of the weld. At this time, the Angle of the electrode should be properly adjusted, and the arc is generally directed to the weld pool to control magnetic bias. See the picture.

1.2 Pass joint

The joint starts the arc 10mm before the arc pit, and when the elongated arc moves quickly to the arc pit, fill the arc pit along the shape of the arc pit, and then weld normally.

Cover welding

Before welding the cover, remove the slag and spatter from the root pass to prevent slag inclusion defects.

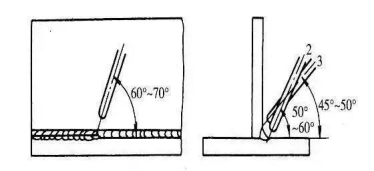

Cover welding welding two, first welding the lower weld, and then welding the upper weld. When welding the bottom pass, the arc should be aligned with the bottom of the root pass, the straight line, the Angle of the electrode should be greater than 45°; When welding the upper pass, the arc is aligned with the root pass along, and the straight rod can also swing laterally. The Angle of the electrode should be < 45°, as shown in the figure:

Theoretical throat: The vertical distance from the base of the joint to the hypotenuse in the maximum intangential right triangle drawn in the fillet weld profile.

Effective weld throat: Minimum distance from fillet weld surface to weld root minus raised part.

Actual welding throat: the shortest distance between fillet weld surface and weld root. For concave fillet welds, since there is no raised part, the effective welding throat is equal to the actual welding throat.

Foot size: Distance from joint root to fillet weld toe.

Toe: The point at which the surface of the weld meets the base material.

When determining the fillet weld size, it must first be clear whether the fillet weld is convex or concave. Convex refers to the slight convex surface caused by the uplift of the weld, which is related to the height of the uplift. The raised height of fillet weld is the same as the strengthening height of groove weld.

If the weld is dented, it indicates that the surface of the weld is concave.

For these two shapes, the weld size of a fillet weld with equal foot height is expressed as "the straight edge of the largest isosceles right triangle obtained in the fillet profile (two feet of equal length)."

Therefore, for a convex fillet weld, the weld foot is equal to the weld size, but for a concave fillet weld, the weld size is slightly less than the weld foot length.

HUARUI alibaba shop:

https://topwelding.en.alibaba.com

https://czhuarui.en.alibaba.com

master@huarui-cn.com

master@huarui-cn.com 86-519-86371071

86-519-86371071 86-519-86371072

86-519-86371072

View More(Total0)Comment Lists