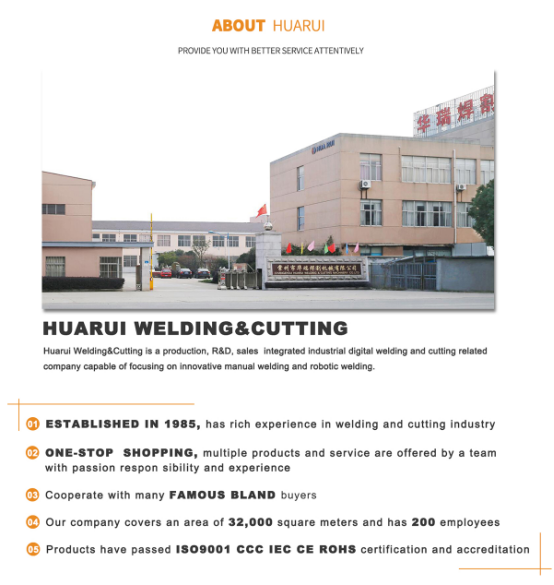

- Welcome To Changzhou Huarui Welding & Cutting Machinery Co., Ltd.!

- About Huarui | Inquiry Form | Contact Us |

中文

中文

中文

中文

The main causes of magnetic bias are as follows:

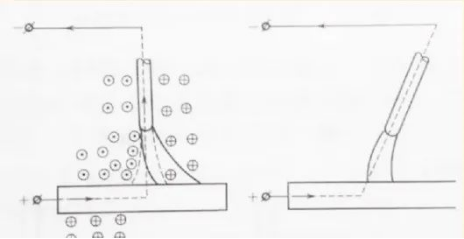

① The grounding cable is not connected correctly

For a long workpiece, magnetic bias will occur if one end is grounded, as shown in Figure A.

This is because there is current flowing through the workpiece on the left of the axis of the welding wire. The magnetic field generated by it is superimposed with the magnetic field of the arc, making the magnetic field line density on this side greater than that on the right side of the arc.

In this way, the larger electromagnetic force on the left side pushes the arc to the right side.

The solution is to ground the workpiece on both sides. The welding wire (electrode) tilts to the right at a certain Angle, enlarges the left space, and makes the magnetic field line density on both sides symmetrical, as shown by the dotted line in Figure b.

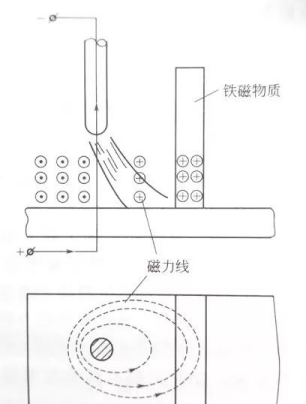

② Ferromagnetic material

The magnetic conductivity of ferromagnetic materials is much greater than that of air. When there is ferromagnetic material (such as steel plate, iron block, etc.) on one side of the arc, the magnetic force line on this side will be sucked into the ferromagnetic material, so that the density of magnetic force line near the axis of the welding wire (electrode) on this side is less than that on the other side, as shown in the figure.

In this way, the force on the ferromagnetic side is less than on the other side, and the arc is biased toward the ferromagnetic side, just as the ferromagnetic material attracts the arc. The larger the steel plate around the arc or the closer it is to the arc, the more serious the magnetic deflection will be.

For the long workpiece, when the arc walks to the end of the workpiece, the arc will be biased to the inside of the workpiece, which is caused by the asymmetry of ferromagnetic material on both sides of the arc at this time. The magnetic permeability area on the inside of the steel plate is much larger than that on the outside, which is equivalent to placing a piece of ferromagnetic material on the inside, as shown in the figure below.

What are the common methods to reduce arc deflection?

Bias blowing will lead to the deterioration of arc operability, welding process instability, poor weld formation, serious welding defects and arc extinguishing, so it must be avoided in the welding process. The methods to prevent magnetic bias are as follows.

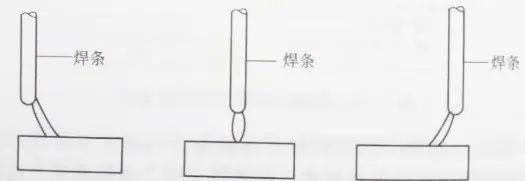

① Try to use short arc, this is because the short arc is not easy to be affected by airflow, the possibility of blowing off. Even when magnetic bias is produced, the deviation is smaller than in the case of long arcs.

② If allowed, try to use AC arc for welding, because AC arc almost will not produce magnetic bias.

(3) Outdoor work, such as strong winds, must take shelter measures to protect the arc. When welding the pipe, try to plug the pipe mouth to prevent the airflow in the pipe caused by blowing.

(4) For the butt weld with large groove clearance, a backing plate is added under the weld to prevent arc deflection caused by heat convection.

⑤ Add a small piece of arc initiation plate and arc extinguishing plate at both ends of the weld, so that the distribution of magnetic force lines on both sides of the arc walking at the end is also as symmetrical as possible.

⑥ Adjust the Angle of the welding wire (electrode) in the operation, so that the magnetic force line on both sides of the wire to maintain symmetry, this method is used in the actual production.

The use of correct wiring methods, for the larger workpiece using both ends of the ground.

⑧ try to use small current for welding.

master@huarui-cn.com

master@huarui-cn.com 86-519-86371071

86-519-86371071 86-519-86371072

86-519-86371072

View More(Total0)Comment Lists